How is the AnyoneGo wheelchair for dogs made?

As you probably already know by now, AnyoneGo wheelchairs for handicapped dogs are created mainly using 3D printers. But what does that actually mean? Do we just start a printer, go for coffee and the bespoke cart for your furry friend is ready in a few hours? Or do we have the individual parts ready in your storehouse, just pick the correct ones, put them together in 30 mins and the wheelchair is ready for shipping?

No, not all! There’s much more work – on the computer, on the 3D printers and by hand – than that. Before you unbox it in front of your dog’s impatient eyes, each wheelchair goes through a rather long process. We understand it’s hard to imagine what goes into producing one of our carts – we didn’t even know it, until we started making them!

Let’s take a look at the different stages of the wheelchair manufacturing.

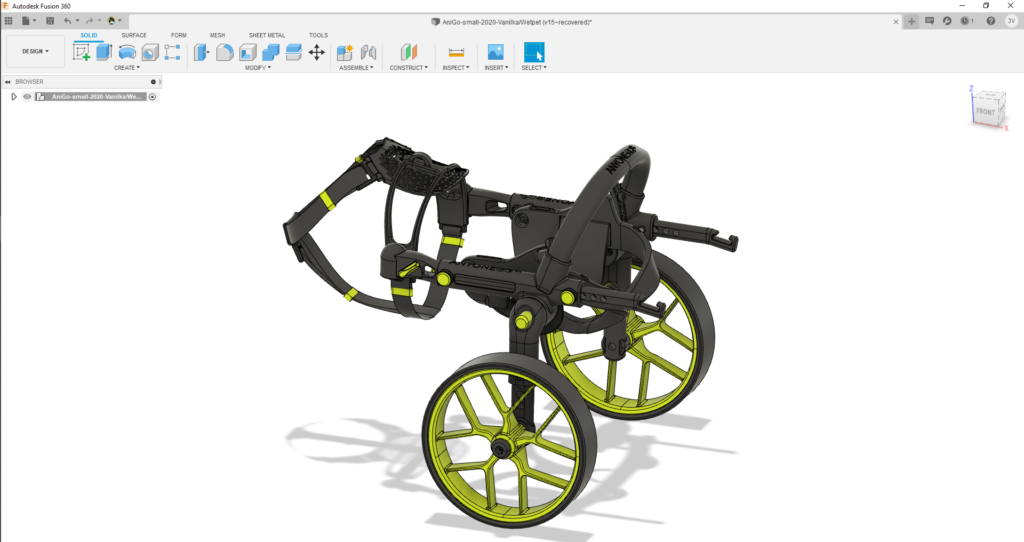

Virtual wheelchair for dogs who can’t walk

At the moment when you confirm your order, we already talked with you and for sure know the most important thing – the measurements of your dog. This means we can start preparing the files for printing.

In the computer, our designer selects the correct 3D model of the cart in the corresponding size and, if needed, adjusts it according to the measurements of your dog. Some dogs are extra special and need bigger changes because of the degree and type of disability. It all happens at this stage.

Once the 3D model of the cart adapted to the needs of a particular client is ready, we virtually disassemble it into individual parts, based on how they will be printed. At this point, a computer program called Slicer comes into play. It’s a special software that prepares the file for the 3D printer, with very specific instructions for each individual print job. And that’s how we move from the computer to the real-life production.

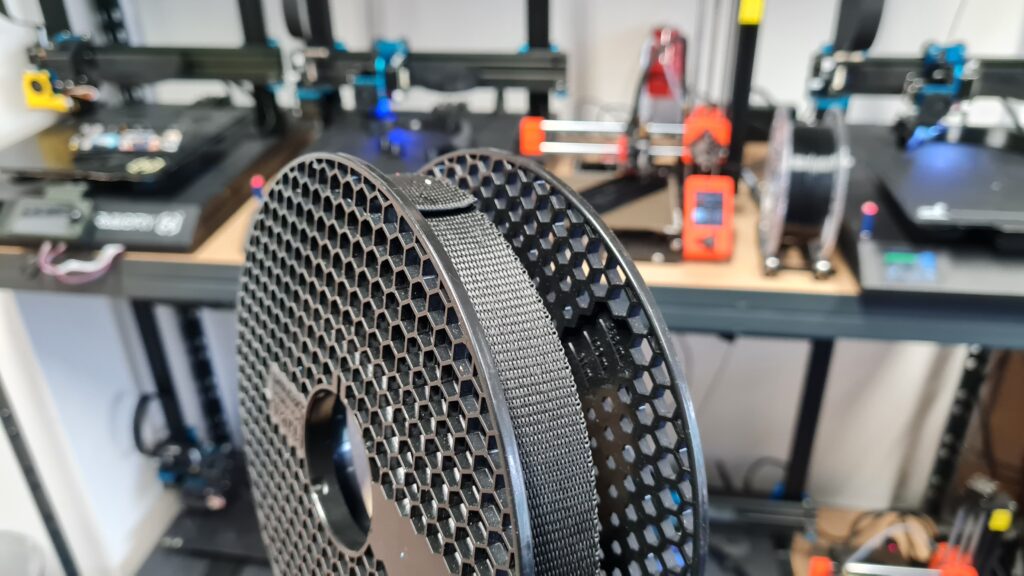

3D print and manual processing

Before we start the 3D printing process, we have to check if it’s the best condition and clean the printing area. Then we just choose the correct filament (material for the 3D printer) and wait for the 3D printer to do its magic – one thin layer at a time.

How long does it take to create one part of the doggy wheelchair? It very much depends on which component we are just printing. The smallest part of the cart – which we call “stone” – is ready in 10 minutes and is so small that, to use the printing time and space most effectively, we always print more of them at the same time.

The biggest part of the wheelchair is the special saddle and it takes 36 hours of non-stop printing!

The dog wheelchair is printed, what’s next?

Most parts of our cart are printed with auxiliary supports. These are not part of the final product, but they are very important, because they prevent the printer from printing in some places. After we remove the finished part from the printed, these supports must be removed mechanically.

That’s why we have many knives, pliers and other tools to make this part as quick and easy as possible. In places where the supports were, the surface is not perfectly smooth so we manually grind and smooth it to perfection.

There are a lot of parts and all of them have to be smooth and pleasant to touch, so on each wheelchair, this process takes several hours of honest manual work in our workshop.

Some of the wheelchair parts, such as the saddle or leg mounts, must also be padded so that they are comfortable. This is also done manually. The rubber padding is cut into the correct shape, glued in place and cleaned again.

One of the few parts of the cart that is not actually 3D printed are the straps. We measure, cut, seal and glue them to the length suitable for the furry client.

Strap material

Finished chest part

Before we can finally start assembling all the prepared components to make a brand new wheelchair, we need to prepare metal screw-threads, so that all the parts click into each other as they should. 3D printers cannot do this precisely enough, so we again use our manual skills – and a drill.

Bear with us, we are almost there! Now we can put all the cart parts together, connect them securely with screws, add pins and straps and make the first quality check. Only now the production phase ends!

Wheelchair for handicapped dog ready for shipping

Before we put your new wheelchair in a box and ship it to you, we do another round of quality check. This inspection is always done by one of the team members who has not participated in the production of that wheelchair.

In this way, we make sure the “inspector” looks at the wheelchair through the eyes of the customer – you!

Oftentimes, this final check is done by ladies from our team – they have a good eye for detail and aren’t afraid to point out things that might not be up to our quality standard. We write a record of the inspection and if something is wrong, the wheelchair returns to the workshop.

If the wheelchair functions and looks great, the last step before packing in the box is to take a picture of the cart.

And then, your wheelchair is on the way to you – and your hendicapped pet.

You can imagine that, when many orders arrive all at once, there’s not a minute to spare. None of the steps described above can be easily accelerated or automated. On the contrary, the whole process requires a great deal of care and perfect planning.

Although 3D printers, standardized sizes and thought-out processes help us a lot, each of our carts is a one-of-a-kind original piece, thanks to a significant degree of customization.

We pour our minds, hearts – and, often, blood – into this work and are very happy when our clients appreciate our honest work.

If you want to make us smile, send us a picture of your happy pup in the wheelchair! (Just don’t forget to hold a leash tight, since now they can run as they please. 😉 )